The previous blog post featured a discussion on what broaching is and its importance in the manufacturing process. This article reviews the industries and businesses that require broaching due to their inherent need for accuracy.

Industries That Depend on Broaching

Automotive

The automotive industry uses broached components in the manufacture of transmission shafts, gears, steering components, and engine components, as well as keyways and splines, in order to ensure reliability, safety, and performance of the vehicle.

Aerospace

Broached components used in aviation and aerospace industries include turbine components, landing gear mechanisms, structural components, and the shaping of high-strength metals. In these two industries, even the slightest defect can result in catastrophic consequences. Therefore, the level of precision required for the manufacture of aviation and aerospace parts is considered non-negotiable.

Defence and Military

The Defence and Military industries require that the components manufactured to be used in these sectors are manufactured exactly to specification, therefore broaching is a technique used to manufacture weapon components, vehicle drive systems, and precision fittings in order to create a level of accuracy that allows the part to perform reliably in the field.

Industrial Machinery and Heavy Equipment

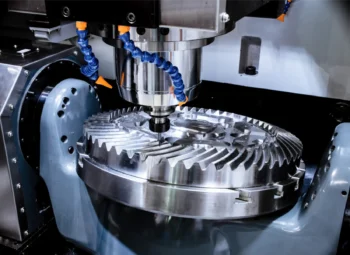

Heavy-duty machinery and equipment found in factories and in construction and roads use the most durable and precision parts available. The skills and capabilities of broaching shops allow them to manufacture gears for cutting tools in addition to unique profiles for the couplings, shafts, and gears needed to withstand continual heavy usage and repeat operations.

Oil and Gas

The equipment used in the oil and gas industry must be able to endure harsh conditions. The needs of this industry often require the use of broaching to manufacture many of the components used in drilling tools and other equipment used by this industry.

Tool and Die Manufacturing

Many tools are made by precision machining. Tooling is essential in precision manufacturing where quality of production depends heavily on the parts manufactured. The precision and accuracy of broaching provide the opportunity to manufacture many cutting tools, dies, and complex shapes precisely and with tightest tolerances. Making even one small error during this process may cause significant damage to the entire production line.

Electrical and Power Transmission

Motors, Couplings, Various Types of Fittings and Gear Drives all require durable and accurately manufactured parts. The performance of these types of machines can depend on the use of accurate and durable components manufactured by broaching.

Medical Device Manufacturing

In order for surgical instruments and mechanical assembly systems for medical use to perform as intended, they need to have a close tolerance and repeatable quality from the manufacturer. The use of broaching provides the precision required to manufacture these types of parts reliably.

Why Industries Choose Broaching

Industries that utilize broaching benefit from the following properties of the method:

- Precision – All parts made using broaching are produced with such an extreme level of precision that they will fit together precisely, and will function correctly.

- Consistency – All parts created through broaching will be created to the same size

- Durability – Parts created through broaching will last longer than any other method available today

- Efficiency – Parts can be produced in larger quantities without sacrificing quality.

Conclusion

Although broaching is an unseen method, it is required in many industries that depend on precision and dependability. Industries such as automotive, aerospace, defence, heavy equipment, and medical devices rely on broaching to keep their operations running smoothly.

If you require high-quality, repeatable, and long-lasting parts, broaching should be your preferred manufacturing method. At Suntech Landriani Machine Tools, we produce reliable machines and tools designed to deliver consistent results. Our experience ensures that every stage of the process is carried out correctly and with precision.